I covered downloading all necessary software in

this post and

presented an overview of the steps to be completed before the first

print in

this post.

An overview of the process of going from a 3-D design to a printed object is available in

this post.

Preparing a .gcode file for printing on a Prusa Mendel 3-D printer is fairly easy with Slic3r.

You'll need your digital calipers to measure the diameter of the filament that you're planning to use.

To start, you need an .stl file. In my

overview post, I indicated that an .stl file can be created with Sketchup and exported using su2stl plug-in, but for this example I'm going to keep things simple and work with an existing .stl file of a 20 mm cube called 20mm_cube.stl which was created by engineglue and uploaded to Thingiverse. Directions for downloading it are

here.

The .stl file contains the design of the object that you are going to print. When you create a .gcode file with Slic3r, you convert the .stl design into a set of instructions for the Sprinter firmware on the Arduino controller to carry out. There are instructions for moving each of the axes, turning on the extruder, turning on the hot end and the heat bed.

Here are the steps:

First, click on the Slic3r icon to launch it.

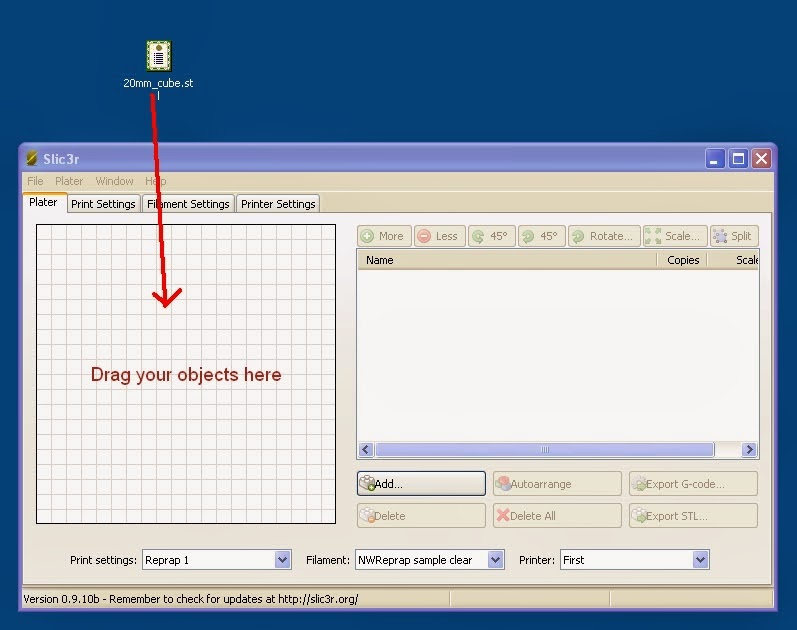

The Slic3r user interface appears.

|

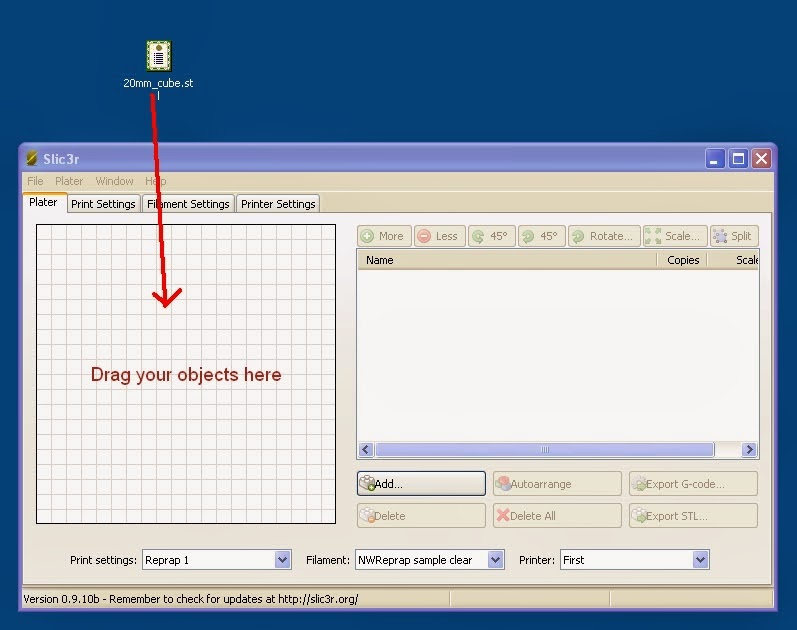

| Drag the .stl file from the desktop into Slic3r workspace |

|

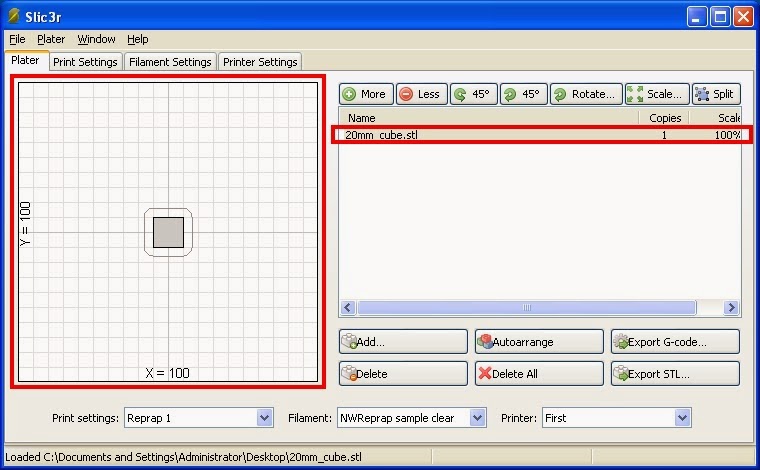

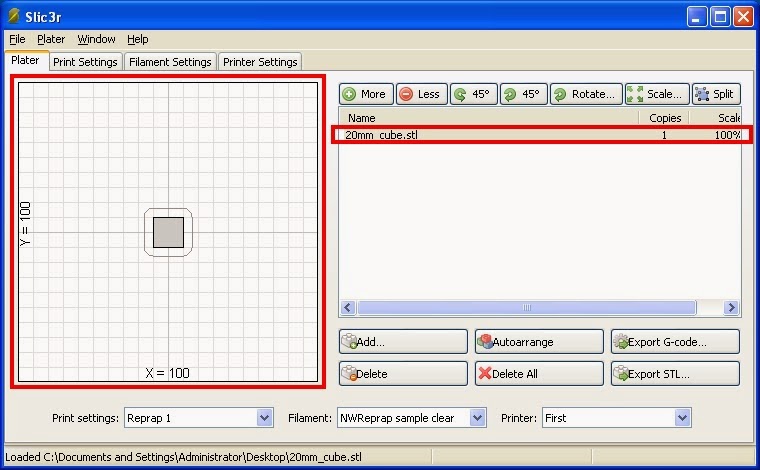

| The 20 mm cube has been added to the layout |

|

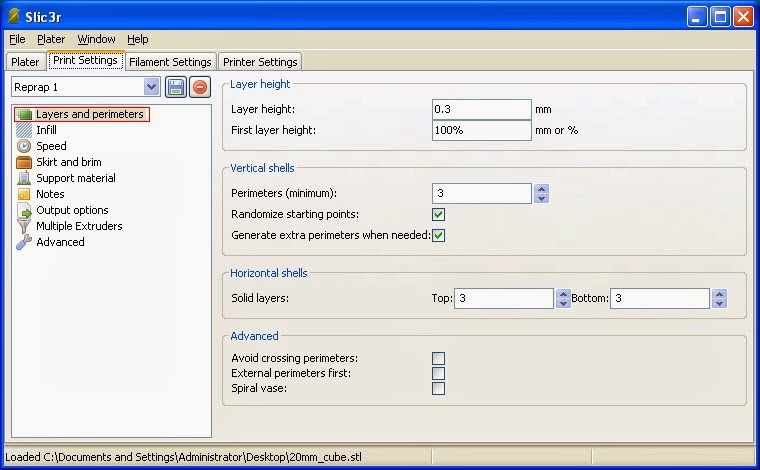

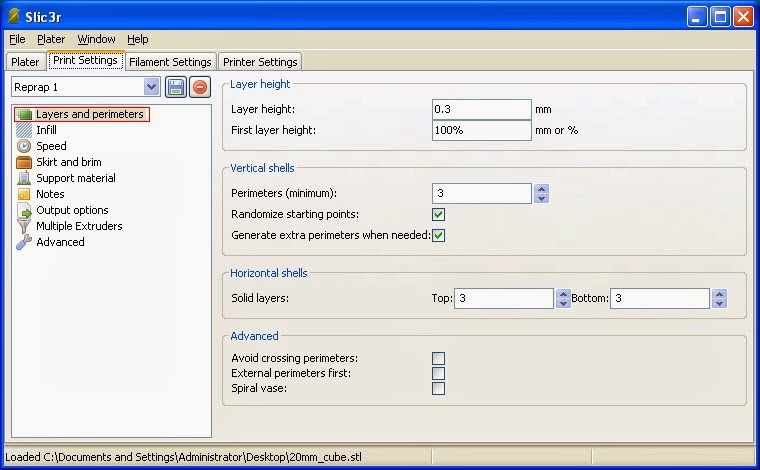

| Check the Print Settings Layers and Perimeters. Make sure that layer height is set to 0.3 mm |

|

| Check the Print Settings Infill |

|

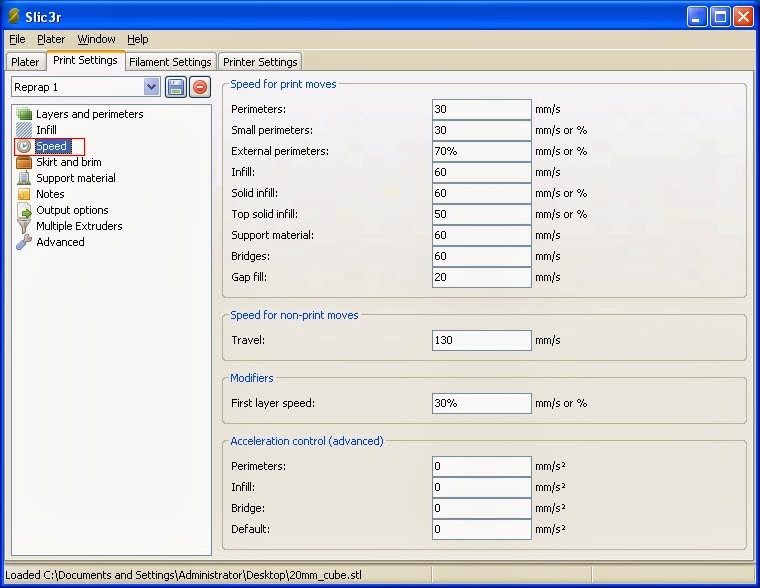

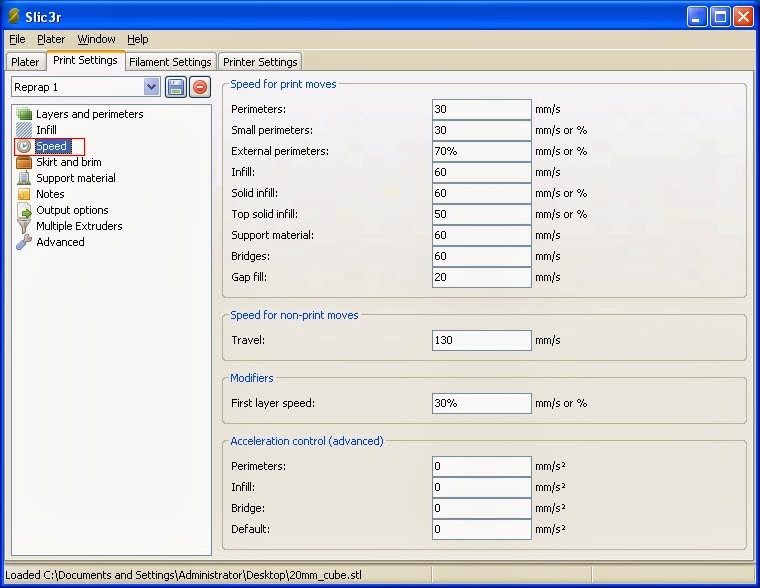

| Check the Print Settings Speed |

|

| Check the Print Settings Skirt and Brim |

|

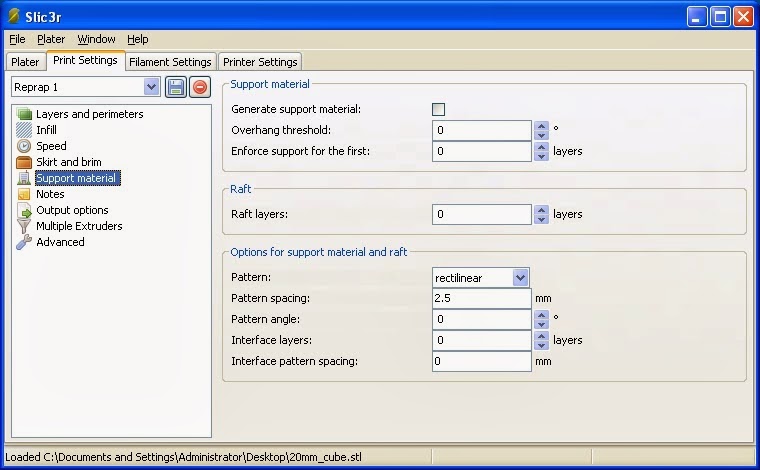

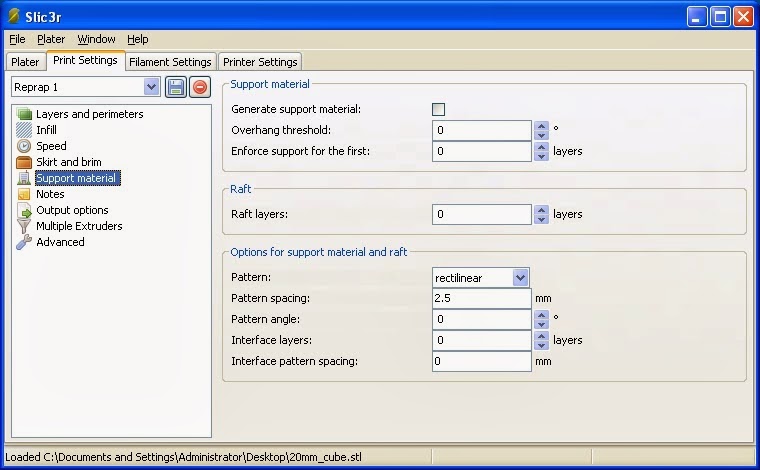

| Check the Print Settings Support Material |

|

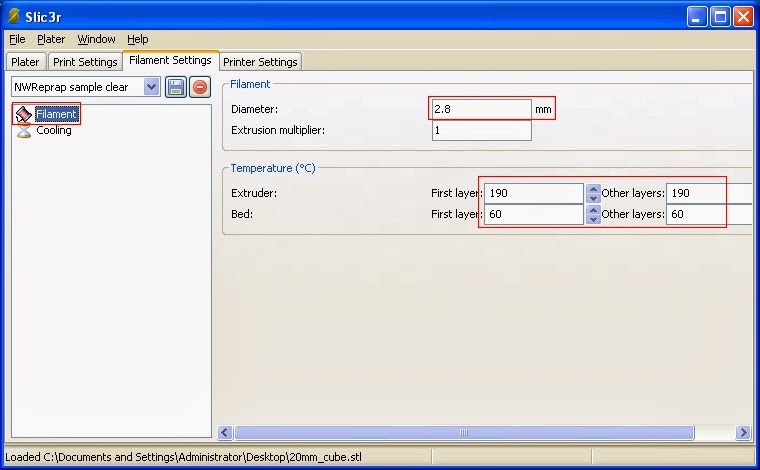

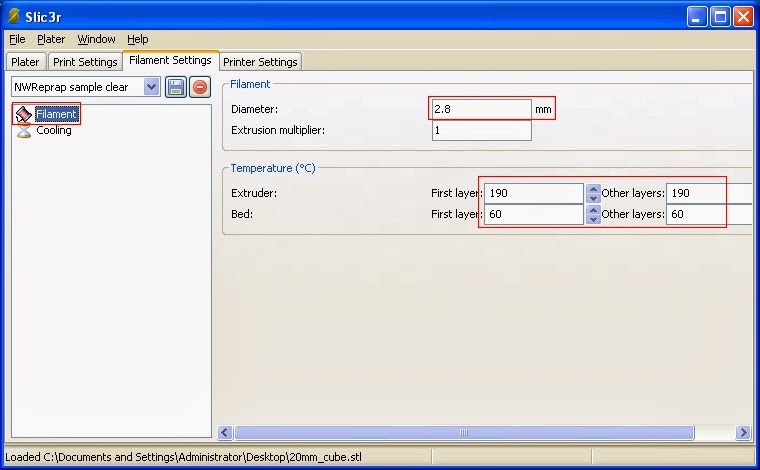

Check the Filament settings. Measure the diameter of your filament with your digital calipers and enter it.

Also it's very important to enter the Extruder and the heat bed temperatures. These values work well for PLA. |

|

| Check the Cooling settings. If you installed the fan that comes with the nwreprap Prusa kit, enable it. |

|

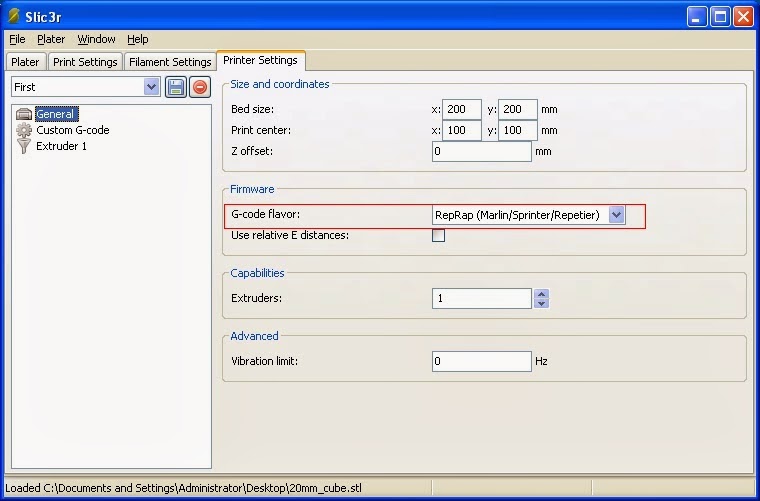

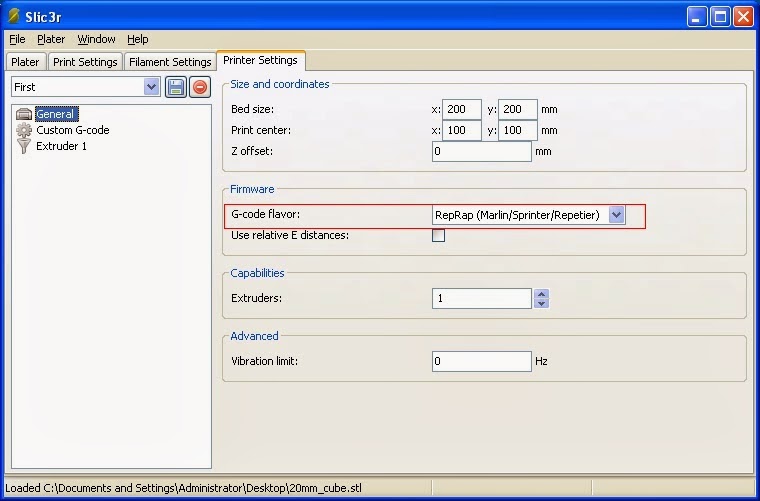

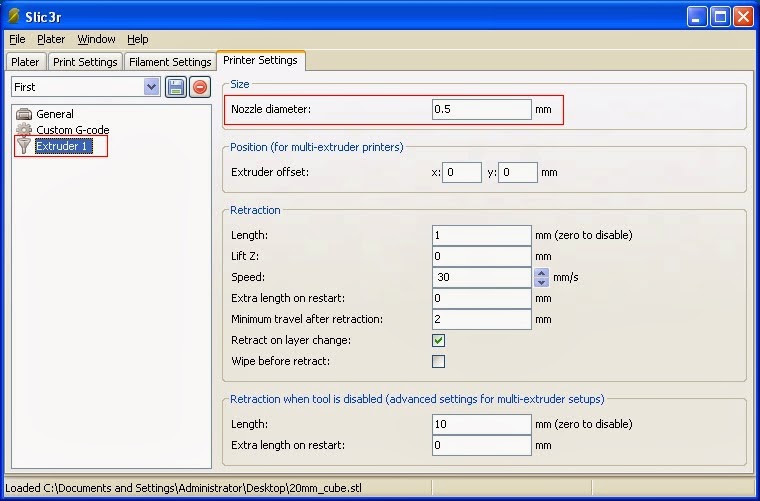

| Check the printer settings. If you've downloaded Sprinter firmware, make sure that the G-code is set accordingly. |

|

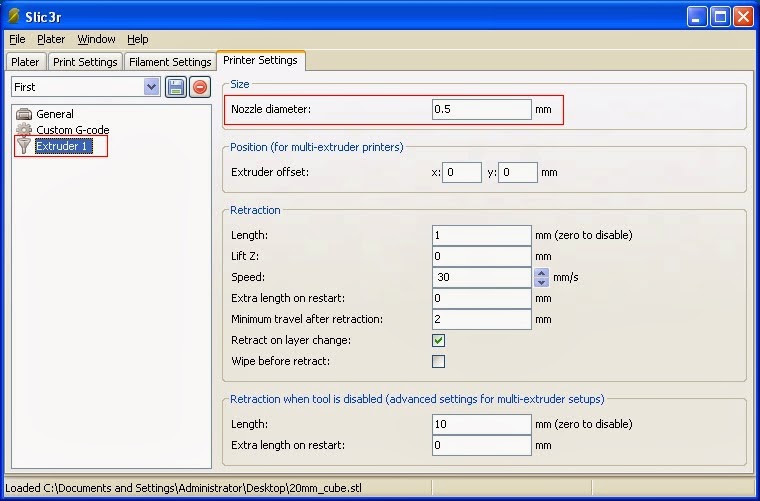

| In Extruder settings, double-check the nozzle diameter. My nwreprap.com Prusa kit has a .5 mm nozzle. |

|

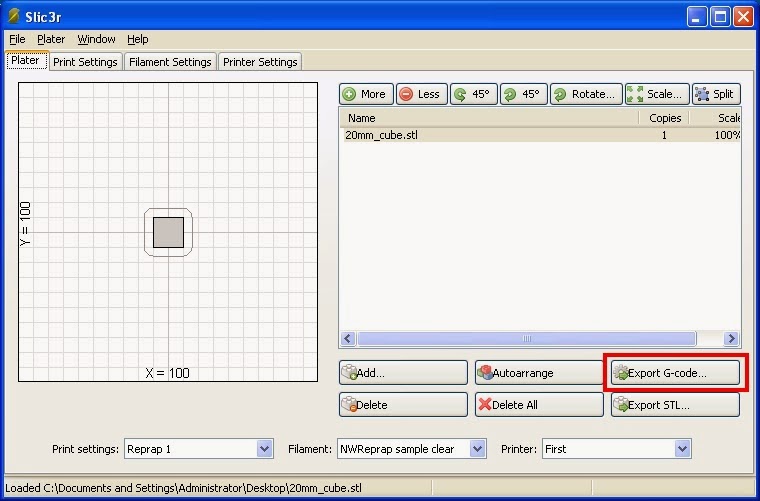

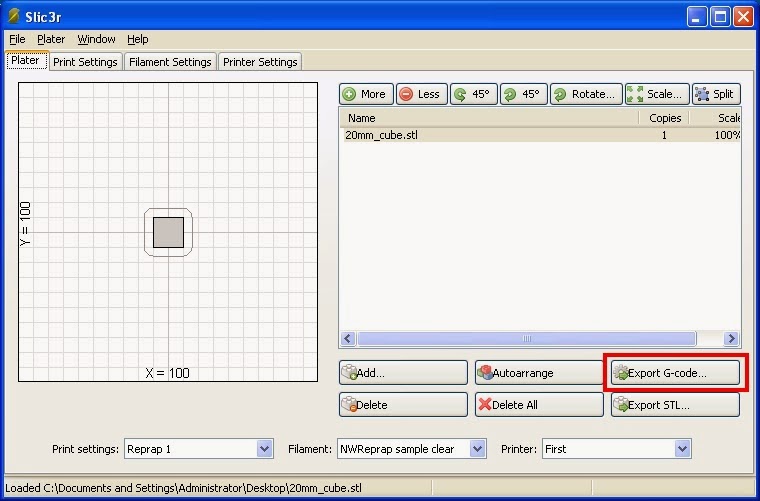

| Go back to the Plater Tab and export the G-code file. |

|

Now you should have a .gcode file ready to be uploaded to your Prusa Mendel.

|

.jpg)

.jpg)